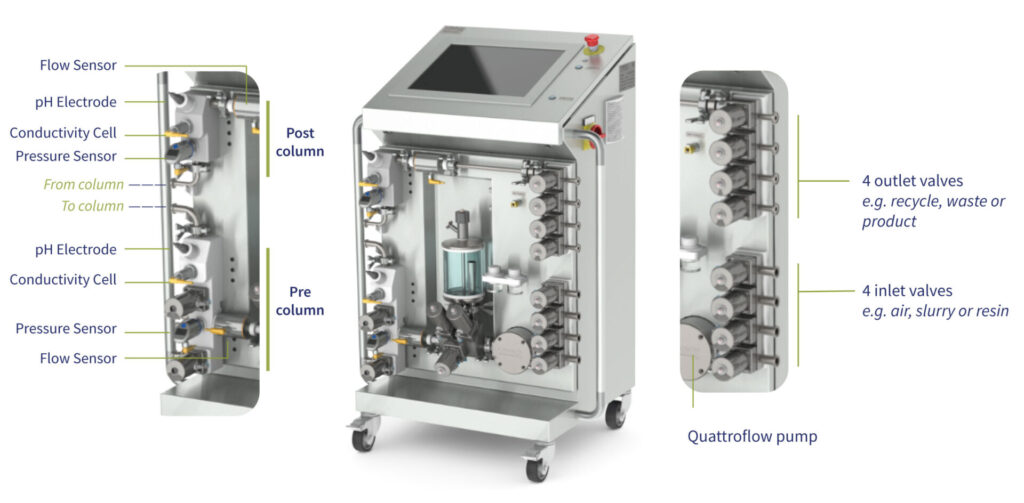

The Proxcys PQ systems are purpose-built Packing and Qualification systems. High-end multi-pump systems, designed for stable and reliable downstream processing column technology and many other processing tasks. Including small and/or large processing hardware – fitted to your R&D lab scale and/or cGMP large industrial scale production of novel recombinant proteins, recombinant antibodies or viral vectors for gene therapy. Compliant to cGMP, ASME-BPE standards and/or ATEX environments.

PQ systems generally include a packing process line, for (semi-)automated packing (loading) and un-packing (unloading) of your column with various process resin types. After packing, additional process lines can be added for automated HETP validation and 21.CFR.p11 compliant downstream processing.

Our PQ systems utilize the user-friendly Companion© Software platform on the HMI – ideal for recipe based automated processing, real-time process monitoring, user depended activity logging in multiple authorization levels and instant HETP and/or batch reporting of your chromatographic process.

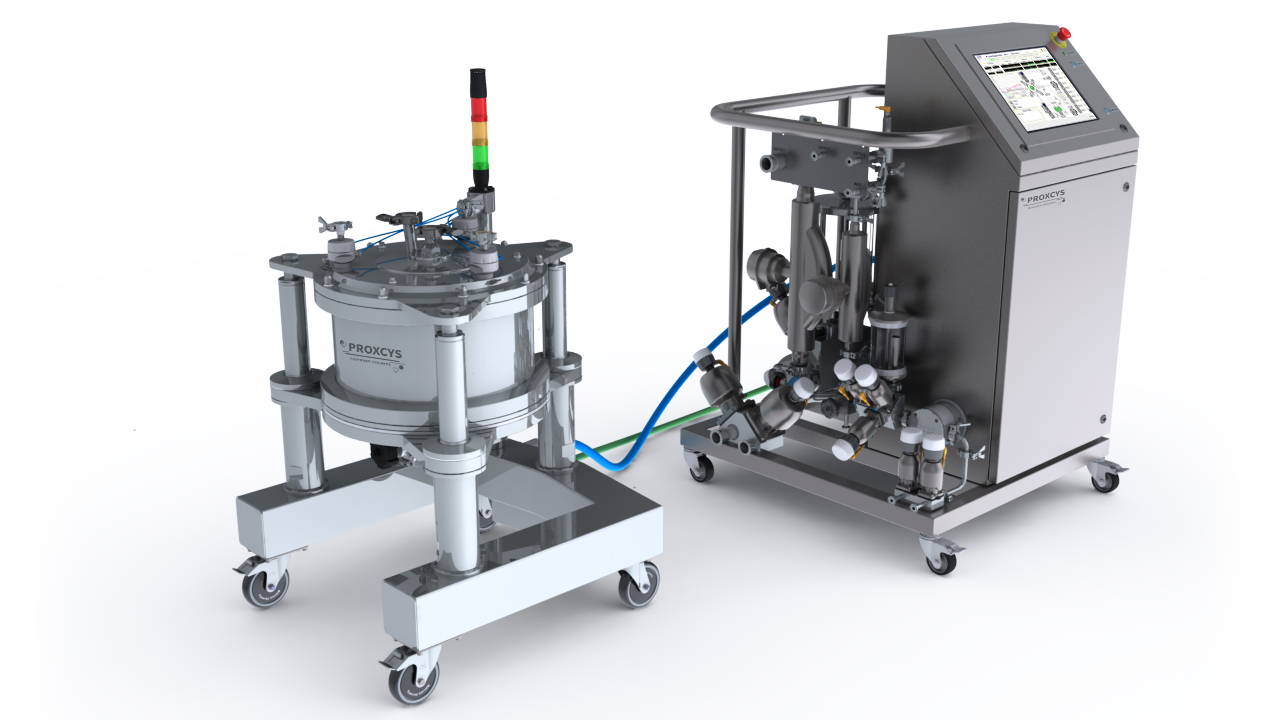

Moreover, our PQ systems provide supreme chromatographic processing in combination with Proxcys Radial Flow Chromatography (RFC) column range – to obtain excellent packing and running performance and gain optimal resolution between peaks. Connect a range of small- or large-scale RFC columns to one single PAT system. For a versatile system set-up, compliant to the highest demands for Packing & Qualification systems paired with a small footprint.

Proxcys PAT20 – Packing and Qualification system

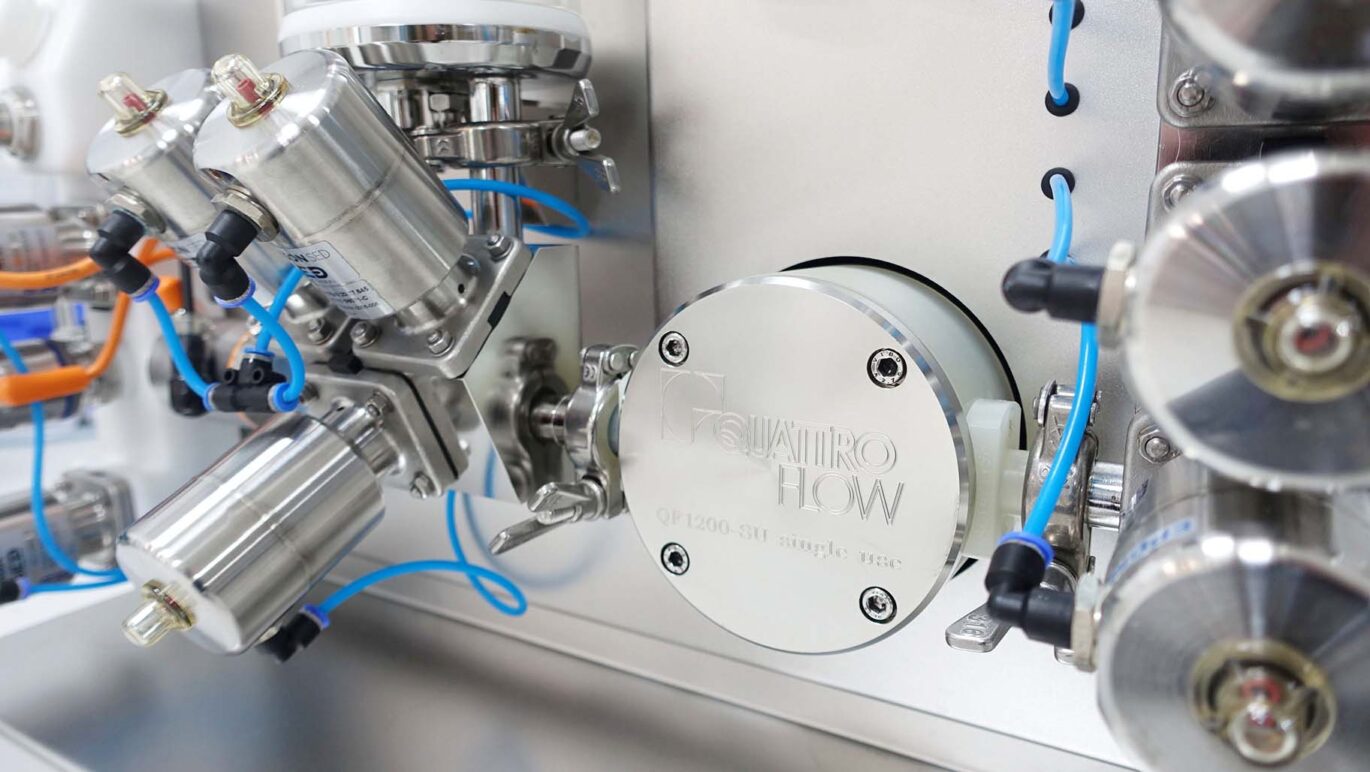

Proxcys Packing & Qualification systems are equipped with single or multiple Quattroflow pumps. Quattroflow displacement pumps excel by their broad flow rate range, their accuracy and exceptional gentle pumping characteristic. This makes them safe to use for a variety of delicate pumping applications.