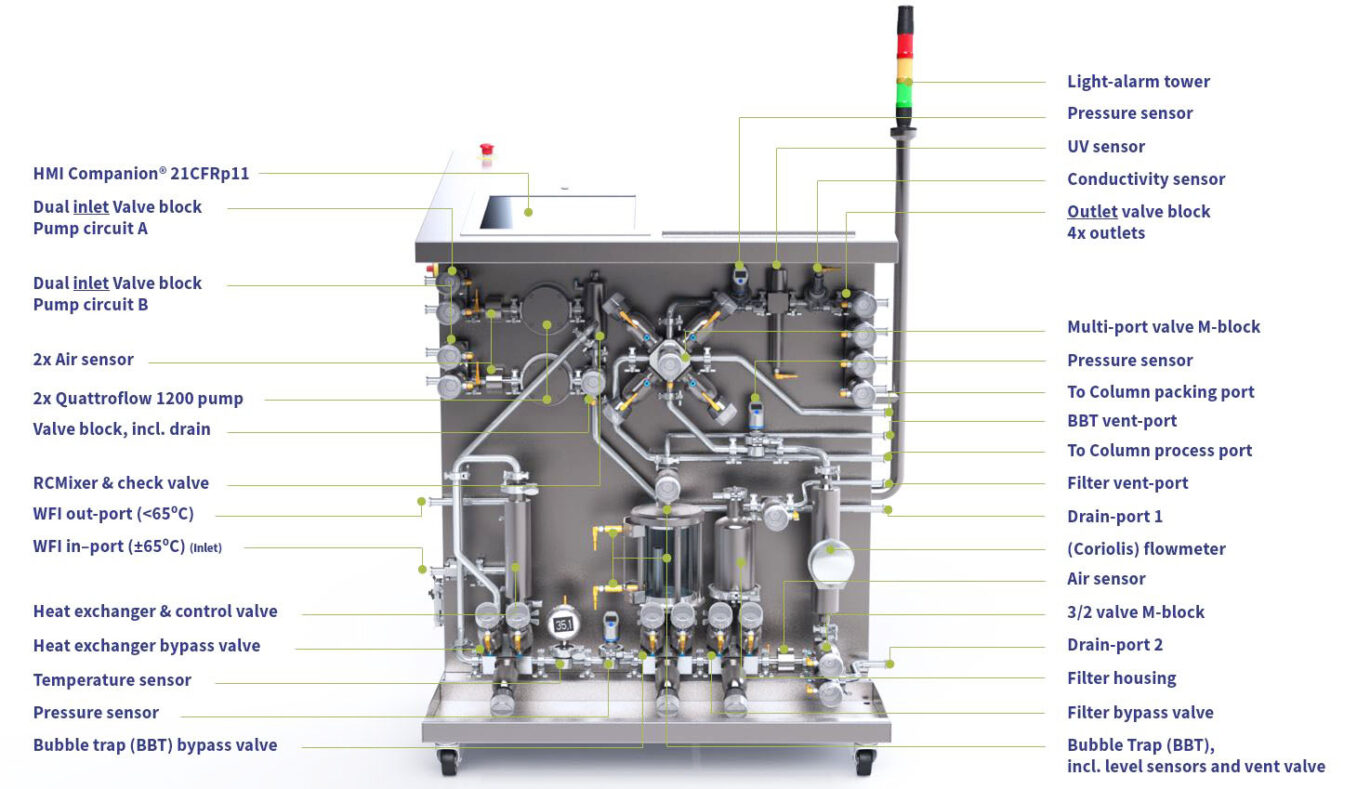

The Proxcys Companion™ allows automated- and manual-, full-featured operation of all system parameters. Real-time level- and trend overview of process values, mirrored onto supervisory SCADA-system for data review, storage and processing. The systems are equipped with dual or triple Quattroflow pumps for flow rates up to at least 20.000L/h. Featuring a heat exchanger (optionally), powerful mixer “RCM” and all process sensors required for accurate control, unparalleled performance on a very small footprint is created.

RCM® – Hygienic valved static mixer

The Proxcys Mixing systems are equipped with the unique Proxcys (patent pending) RCM® high efficiency valved static mixer, that delivers a perfect mixture over a large flow-rate range while preventing undesired back mixing by the RCM® internal valve. Instant makeup of mixed feeds reduces makeup losses. Designed to efficiently mix two liquids in mixing ratios exceeding 1:20 whilst the desired accuracy can be set by user. This flexible system reduces wasted liquid during buffer makeup to a minimum. The RCM® will even allow shear-sensitive liquids (e.g. blood-plasma) to be diluted without foaming.

Customization

Proxcys excels in equipment customization, whilst maintaining the smallest possible footprint. Together with the client, the process-requirements and possibilities are reviewed and the equipment is designed and tailored accordingly. Proxcys Mixing systems are thus fully designed upon client-specification and are available from “Benchtop-models”, for R&D/ small-scale work, to fully-automated skids suitable for full-operational process scale.

The entire flow-path, from process-inlet to -outlet is built-up modularly according to e.g. URS or Client-P&ID.

- Dual or triple pump configuration

- Flowrates between 1L/h – 20.000L/h

- Flow path

- Number of inlet- and outlet valves

- Sensors and sensor positions

- Connection-type and -dimension

- Inline Bubble trap with or without bypass valve

- Component and sensor selection – flexibility in manufacturer and type