Scaling up Radial Flow Chromatography

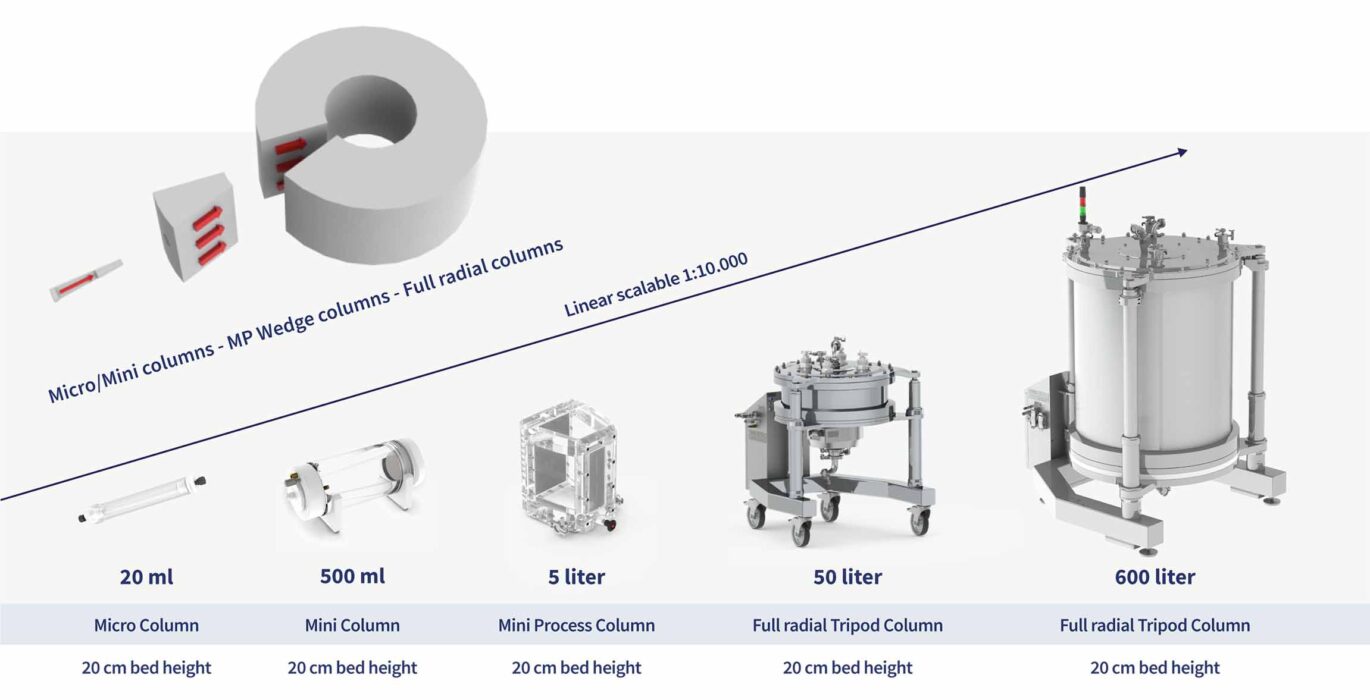

Proxcys HP-RFC columns are linear scalable from Lab- to Industrial size. The Radial flow technology provides an efficient way to scale up volumes and flow rates linearly, whilst maintaining the smallest footprint.

Flow distribution, frit architecture and -its resistance, bed height, column hydrodynamics and all other physical parameters are maintained from small scale columns up to a full radial column, making the Proxcys radial chromatography technology truly linear scalable.

Based on the available -or desired- process requirements and restrictions, Proxcys often develops a tailored scale-up plan, fully adapted to the process parameters. For such a Scale-up and development plan, the Proxcys Technical Sales engineer and Product Specialists work closely together with the Client, to determine the process parameters and project scope. The final scale-up plan can contain basic recommendations, up to detailed consecutive upscale steps, including the recommended equipment.

In general, a scale-up and development study contains the following;

- Determination of process parameters – Exploring

– Desired final upscale volume

– Desired bed-height (range)

– Resin (type, beadsize, residence time, etc.)

– Timeline - Scale-up path – Proxcys experts

– Selection of best suitable bed height(s)

– Selection of best suitable bed volume and intermediate step(s)

– Selection of possible columns based on the bed height(s) and volume(s)

– Present path to Client - Execution of scale-up path – collaboration between Proxcys and Client

– Selection & preparation of required hardware (systems and columns) – Proxcys

– Column packing study to determine optimal column packing conditions – Proxcys

– Evaluation of (pre-packed) columns by Client, feedback findings to Proxcys - Reporting and recommendations

– Findings are documented and shared in a detailed report, including summary and future recommendations.

Packing optimization study

Series of consecutive experiments with a HP-RFC column to optimize and determine column packing- and running parameters. In-house work by Proxcys experts to perform multiple (packing) experiments in order to further optimize the packing protocol for your RFC column.

For example, the work can consists of:

- Selection and preparation

– Selection & preparation of required hardware (systems and column).

– Cleaning, assembly and optimization of laboratory set-up.

– Frit architecture investigation. - Packing optimization study

– Column packing study to determine optimal column packing conditions for the resin(s). - Reporting and recommendations

– Slurry concentration and packing recommendations.

– Findings will be documented and shared in a detailed report, including future recommendations.

Resin compatibility study

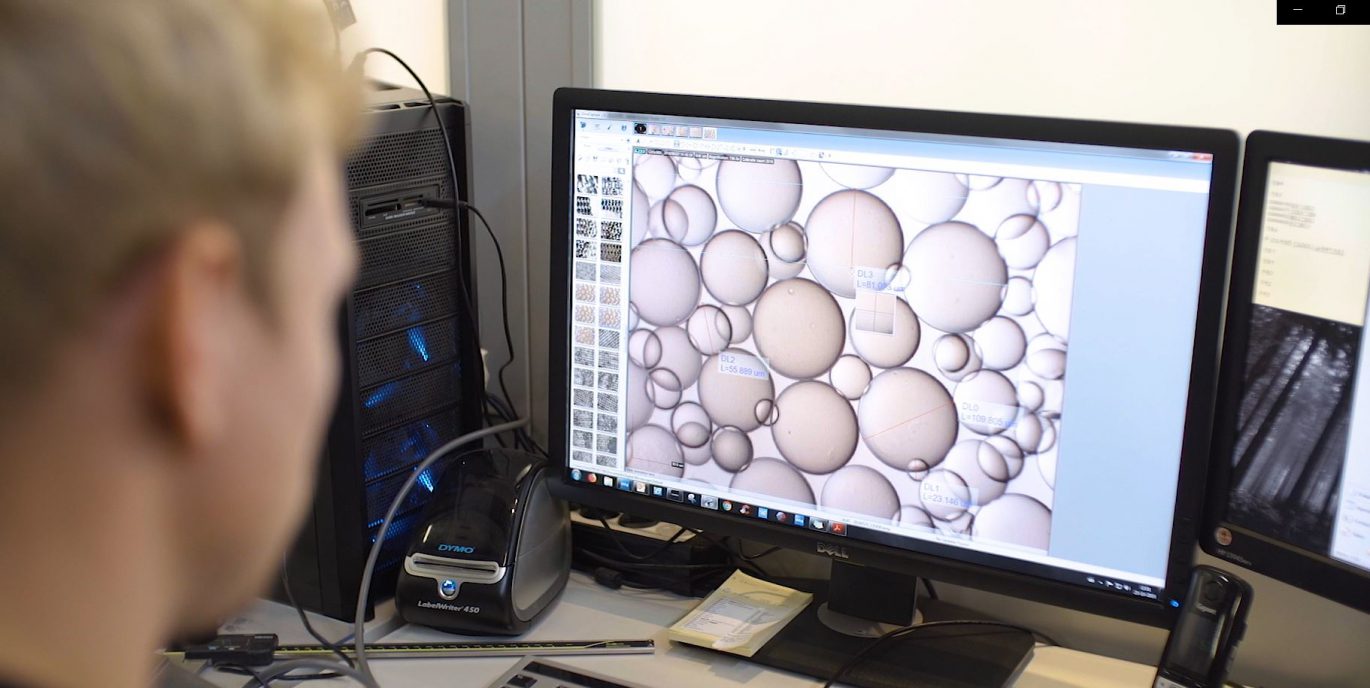

Microscopic resin investigation to confirm bead quality, column compatibility and configuration, including recommendation report.

Proxcys experts will investigate the resin to determine the optimal parameters for column packing and later processing. A resin compatibility and packing-study is recommended to further optimize the column set-up and to determine the packing flow-rates and ideal slurry concentration. All data will be summarized in the Proxcys Qualification report.