In comparison to axial columns, radial columns with short bed height are very efficient in space and weight demand at larger scale. To be able to reduce column width for axial columns, they mostly operate at a maximized bed height of 20cm. For radial columns this limiting factor does not exist.

This means that for radial columns the throughput will be higher, the process duration shorter and the operating pressure lower. For the same linear velocity, the flow-rate is much higher.

Radial column processing features a dramatic reduction of footprint. Packing a HP-RFC column even with the shortest bed height is very fast, better manageable and uniform. Increasing the column volume does not influence packing performance since radial flow chromatography columns are linearly scalable. RFC equipment is 75% lighter and 80% more compact than axial equipment.

How to transfer Axial process to Radial.

Residence time is a popular parameter in transferring processes. In fact this is only valid when the bed height of the column remains the same or is very similar. Radial columns offer a stable low bed-height bed at large bed volumes. With Radial one can combine increased productivity, reduction of resin costs and increased product yield.

Processes often run more than proportionally faster, because the pressure buildup is more than proportionally less in radial columns. Thanks to this physical fact, residence time needs to be translated into (average) LV and this value can be increased a bit.

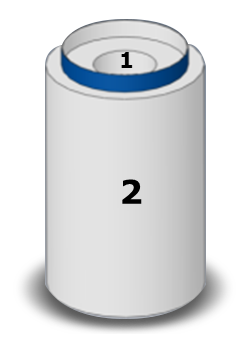

The transfer is done by using the reference area value which is provided with each radial column.The reference area is a an imaginary cylinder (blue) which represents the corrected average surface area between the outer (2) and inner (1) boundaries Proxcys indicates the reference area in the type number of Pilot and Process HP-RFC columns e.g. CA 602 = 6cm bed height with a reference surface area of 0,2m2. Hence this column will have a flow of 200L/hr at 100cm/hr.

Axial

Processing velocity expressed in LV

- Residence time / surface area

- Normalize to cm/hr

Radial

Axial LV projected on Radial reference area

- Correct for reduced pressure drop

- Correct for increased loading efficacy

Radial processing superior to Axial:

- Pressure drop 20-50% reduced

- Loading efficacy improved

- Complex feed handling improved

- Binding kinetics (dynamic capacity)

- Process robustness (larger process tolerance window)

- Higher Throughput

- Shorter processing time